The Damaging Cycle of Moisture

From the moment a Sealed Unit leaves the shop floor, it is a candidate for failure.

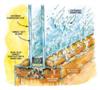

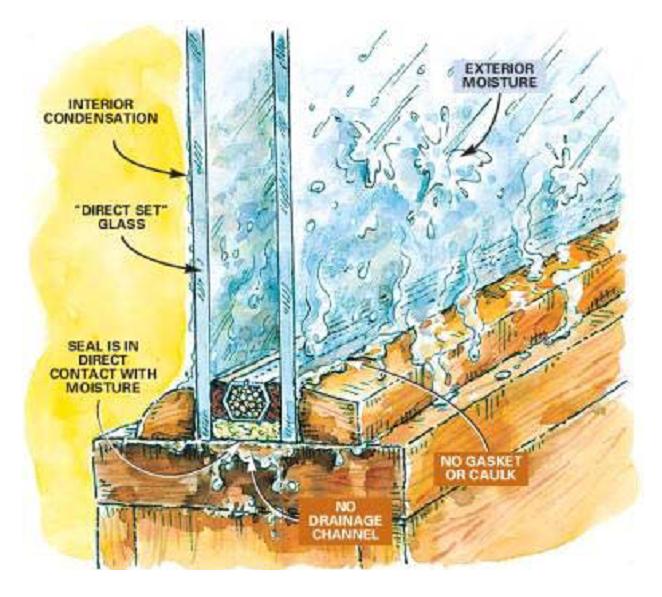

Moisture diffusion into a sealed unit is unavoidable and continuous. Manufacturers deal with this reality by loading adsorption material, or 'dessicant', in the spacer bar construction of every unit. This material has one job - to bond with water molecules. The material comes in the form of beads, similar to those you find accompanying new leather and electronic products, or as a blended compound, often a black butyl or cork-like wafer.

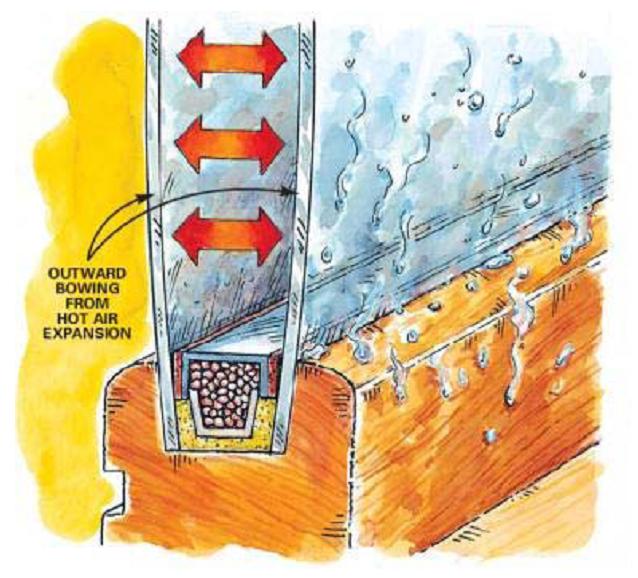

Every Sealed Unit has a finite capacity of how much water it can hold ('hide'). Over time, as moisture accumulates, the unit finally reaches a threshold saturation point, it becomes visible as condensation between the lites of glass (this is directly associated to the falling dew point between the panes of glass!)

In the early stages of visible failure, a mist may appear and disappear through the natural cycle of evaporation. As the saturation point is further exceeded though, the dangers begin, as moisture becomes permanent, progressively leaving deposits, stripping the insulating properties of the unit, and scarring the glass. Once scarred, the unit may not be salvageable.

Damage